Welcome to dependability backed by expertise

Explore the innovations and technical expertise shaping the future of power.

Kent Roberts has a very personal connection to preserving a 5-acre parcel of oak trees and other vegetation in Mineral Point, Wis. where the Community Involvement Team at Cummins Emission Solutions has been working for the past three years. The park-like area, known as an oak savanna, is named for his former teacher who started the preservation effort. “My former teacher Don Hawkins, who the

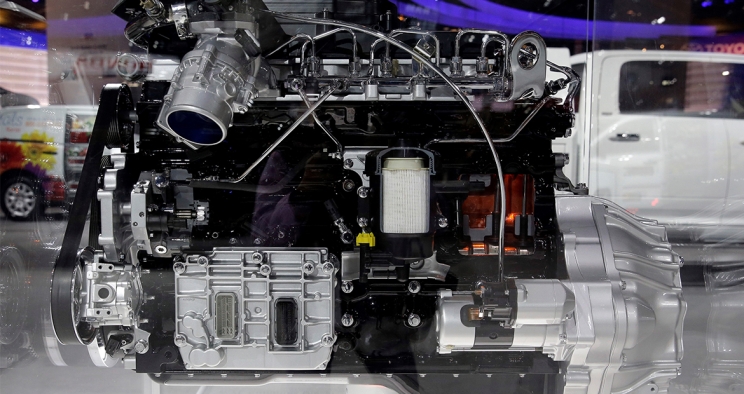

Cummins and Peterbilt Motors Company say a demonstration tractor-trailer they partnered on achieved a 54 percent increase in fuel economy during testing in the fall of 2012, averaging nearly 10 miles per gallon (mpg) under real world driving conditions. The “SuperTruck” developed by the two companies features a higher-efficiency engine and an aerodynamic tractor-trailer that significantly reduc

With today’s fuel prices, getting the most miles out of every gallon of fuel is a major priority. There are a lot of factors that go into the amount of fuel you use in a given day, and your Cummins Turbo Diesel is one of them. Some simple adjustments may help you save on gas costs when driving your 6.7L Cummins RAM. At a very basic level, the more work your engine does, the more fuel you use. T

Cummins technology was in the spotlight in a recent episode of Motorhead Garage highlighting the history of Cummins diesel technology. As part of the “Big Rig” series, the episode, hosted by Sam Memmolo and Dave Bowman, aired on Fox Sports Net (FSN). Motorhead Garage has reunited the pioneers in automotive how-to TV – Memmolo and Bowman – to analyze and advise viewers of the latest product

The Cummins High Mileage Club for Turbo Diesel owners recognizes our customers for all the miles they have driven with their Cummins Turbo Diesels. This quarter, we recognize Jeff Doster from Hampstead, Md. When Jeff bought his 1996 3500 RAM dually, it had been used and abused. The interior and exterior needed a lot of work, but the Cummins Turbo Diesel was running well. So Jeff fixed up t

At Cummins, we have a long history of successful joint ventures, and our association with Westport Innovations, which began in 1988, is no exception. Cummins Westport Inc. (CWI) was formalized as a joint venture business on March 7, 2001. Since that time, it has become a significant force in the transportation industry. Over the past decade, Cummins Westport has grown to become the world’s lead

Cummins' Rocky Mount, N.C. Plant Manager Ken Anderson takes an active role both inside the plant and working with educational institutions to develop the next generation of plant employees. Ken Anderson, plant manager of Cummins’ Rocky Mount Engine Plant, recognizes the interdependence between the Company’s operations and the North Carolina region where his 2,100 employees and contrac

The Additive Manufacturing Approach The prototyping industry utilizes additive manufacturing to generate 3D parts using plastic media. This technique is a recognized approach for providing a visualization aid so that key considerations such as ease of manufacture can be assessed, for example. The manufacturing method reduces the time taken to develop new products and improves the collaboration

With the advancement of new electric and hybrid technologies picking up pace such as electrification and stop-start technologies to improve commercial vehicle fuel efficiency and reduce CO2 emissions, Cummins Turbo Technologies needs to understand what the impact of these new automotive technologies will be on their air handling technologies. Through this project Cummins Turbo Technologies is d

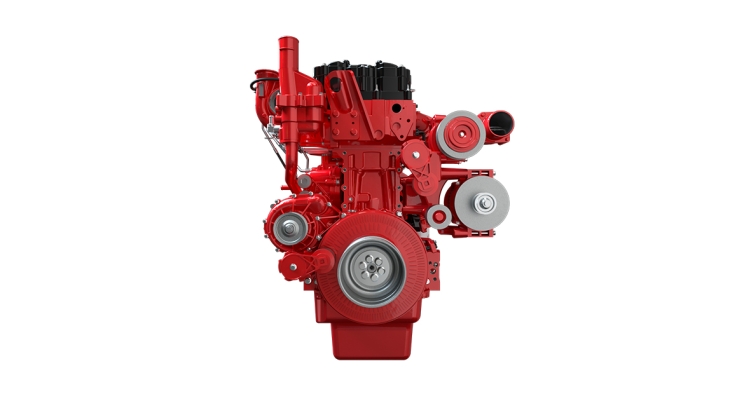

Highly Durable, Highly Efficient and Compact Turbochargers Are Becoming Increasingly Desirable Over the past few years, the market has seen global engine and vehicle manufacturers shift their focus from emission driven regulations to fuel economy improvements to insulate their customers from rising fuel prices. With fuel prices remaining high, Cummins Turbo Technologies is committed to focusing o

The debate around turbocharger and engine technologies in the off-highway sector has historically been one that focuses on reliability and durability. Operators in these markets need to minimize the downtime of their equipment to ensure there isn’t a commercial impact on their businesses. For example, mining companies face the challenge that they consistently need to identify and prevent issues

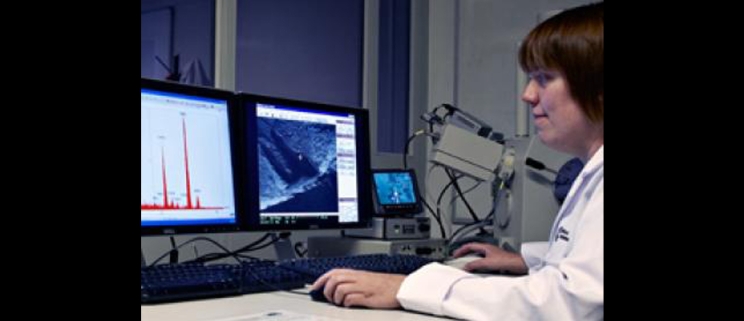

Tribology within Turbochargers There are numerous tribological interfaces, commonly termed tribosystems, within a turbocharger. Some of these, such as the rotor bearing system, are lubricated and operate at temperatures less than 200 °C. The variable geometry and wastegate systems are examples of high temperature tribological interfaces within a turbocharger which are subject to temperatures be

Novel Solutions for Materials Engineering Increased demands are being placed upon turbochargers as a result of ever more stringent emissions regulations, a necessity for improved product performance and reliability and a requirement for a wider product operating range. Consequently, a greater level of stress is placed upon the materials from which turbochargers are manufactured. In order to achie

The news is good from Padarwadi, but there have been some difficult times, too. It’s been more than two years since the tiny village in India, accessible only by foot, received a generator converted by engineers at Cummins India to run on oil from a local seed. The generator powered a small mill to husk the rice that village residents grew so they didn’t have to make hundreds of trips to the

Since January 2011, the Cummins Darlington (U.K.) Engine Plant hasn’t sent any waste to a landfill. That’s nothing in more than 16 months. Zero. Nada. And on top of that, the plant has reduced associated annual operating costs by $159,000. Darlington achieved its “zero landfill” status by making waste reduction a plant priority, and then using processes, tools and resources – most notab

A diverse and inclusive work environment helps all employees work more effectively and efficiently, both with their local teams and with colleagues around the world. This ability to work locally and globally allows Cummins to focus on leveraging the full power of the Company for its customers no matter where they are located. One way Cummins works to create the right environment for success is

Mark Levett, Cummins Vice President and General Manager – High Horsepower Business, talks about the QSK95 engine at its unveiling in Seymour, Ind. It’s hard to imagine something eight feet tall, 14 feet long and capable of producing 4,000 horsepower could ever be considered “green.” But Cummins’ new 16 cylinder QSK95 engine, the largest high-speed diesel engine the Company has ever built, ha

Combine the talents of a self-described “eco-child” with a cost conscious facilities leader and an engaged and committed group of employees and you get Cummins Turbo Technologies (CTT) in Huddersfield, U.K., one of the Company’s leading facilities for energy conservation and other green practices. Jennifer Hirst, an Energy Engineer at CTT Huddersfield, and Richard Keane, CTT’s Facilities Manage