Welcome to dependability backed by expertise

Explore the innovations and technical expertise shaping the future of power.

Cummins executive Pamela Carter, the first woman to lead one of the company's four main business units, will retire as president of the Distribution Business effective April 1, 2015. Carter joined Cummins in 1997, initially serving as the company's Vice President - General Counsel and Corporate Secretary. Prior to joining Cummins, she served as the state of Indiana's first African American woma

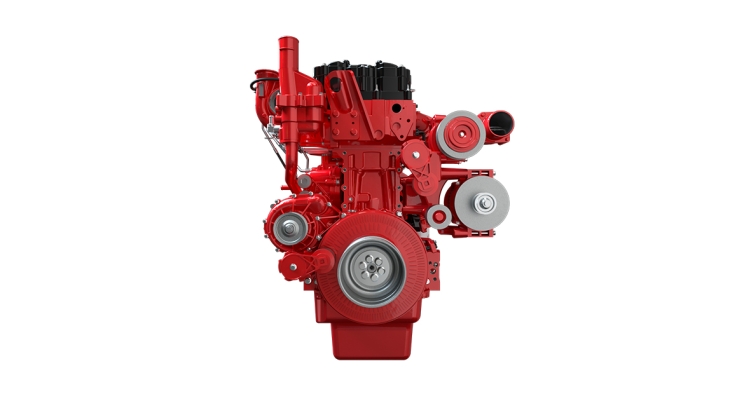

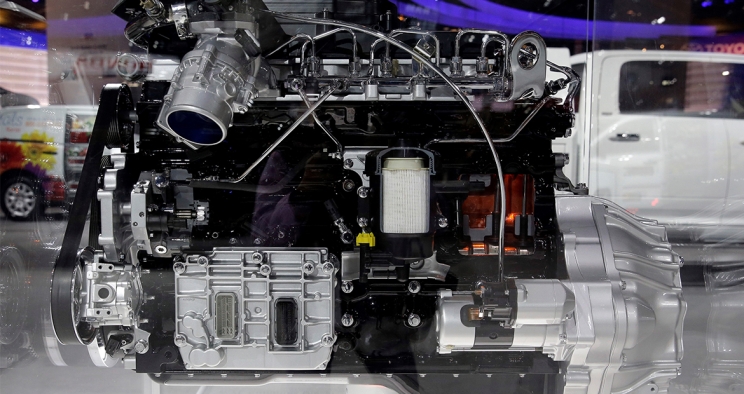

It’s here. At 8:05 a.m. ET, the 2016 Nissan Titan XD full-size pickup powered by a Cummins 5.0L V8 Turbo Diesel made its much-anticipated debut at the 2015 North American International Auto Show. At the heart of every great vehicle is a strong engine. A strong 5.0L V8 Diesel Cummins, that is. #NissanNAIAS pic.twitter.com/OUrAoNFAqe — Nissan (@NissanUSA) January 12, 2015 Th

1/16/2015 Update - Standings after Stage 12 Twelve out of 13 stages are now complete at Dakar, and all three rally trucks (powered by Cummins) for the Ginaf Rally Power team remain in the thick of things. After Stage 12 - which took competitors approximately 525 miles from Termas Rio Hondo to Rosario - Wulfert Van Ginkel sits in 12th place, Jos Smink sits in 17th place, and Edwin Van Ginkel

For the eighth year in a row, the Human Rights Campaign (HRC) has awarded Cummins a perfect score in the 2013 Corporate Equality Index as part of its Best Places to Work initiative. This is a big recognition for Cummins, a company that prides itself on diversity. Our CEO Tom Linebarger had this to say about the award: “Cummins is honored to be recognized by the Human Rights Campaign for the

Recently, Cummins honored seven of its employees with the Company's highest technical award for their work on two inventions. Mark D. Akins, Bryan W. Milburn, Dennis M. King and Greg M. Pataky were recognized for their work to improve turbocharger technology on Cummins’ midrange engines. Steven M. Bellinger, Brian C. Tyler and John F. Kalill received the 2012 Perr Award for developing a system and

On Nov. 15, Cummins officially opened its Cummins Angola operations. The project is a joint venture partnership with Angolan Project Net, which is led by CEO Jorge Jover. Located in Viana Industrial Park outside the capital city Luanda, Cummins Angola currently occupies 1,000-square meters of office and parts outlet space, as well as 1,750-square meters of warehousing. Cummins is working cl

Cummins Power Generation’s manufacturing facility in Fridley, Minn., is returning parts of its grounds to their native prairie state, potentially reducing water and fertilizer use. A grass burning took place in July in space that will become a small prairie as part of a pilot project at the site. Another area by a new test cell will also be seeded with prairie grass this fall. Fridley Plant

Cummins South Africa employees decided it was not enough to merely increase recycling in Alexandra Township, an informal settlement of Johannesburg, South Africa, near the Company’s offices in Kelvin. To really address Alexandra’s problems, they had to look for ways to reduce the area’s population of rats – some the size of small cats. And the best way to control the rat population, they con

The Cummins campus in Guarulhos, Brazil, is near several major highways and São Paulo’s international airport. Traffic in the area is frequently bumper-to-bumper. Green space is limited. But over the past three years, nearly 800 Cummins employees have planted some 5,000 trees in the area. Not only has their work helped beautify the city, the air is cleaner, dust has been reduced and temperature

Passengers traveling between the borough of Hackney and historic Victoria Station have been given a glimpse of the greener future of London’s iconic bus system. A new bus inspired by the original double-decker Routemasters and powered by a Cummins ISBe 4.5 litre engine, carried locals and visitors using state-of-the-art hybrid technology. Cummins engineers worked closely with Wrightbus in

Major infrastructure upgrades can be very capital intensive, and the Jamestown Engine Plant (JEP) in western New York hadn’t seen many over the last 40 years. All that changed in 2012, however, including the plant’s approach to energy use. A “deep energy retrofit” project is underway at the nearly one million square foot facility as part of a corporate-wide commitment to improving energy effici

Water can be a scarce resource in certain regions of Mexico, but Cummins plants in the country have implemented a variety of initiatives to use the resource wisely. At Cummins New and ReCon Parts in San Luis Potosi, plant officials are monitoring soil moisture in green areas to create efficient irrigation methods. They harvest rainwater from a cistern with a capacity of 3,612 cubic mete

In Fridley, Minn., Cummins is making significant strides to reduce production waste thanks in part to a partnership with Rise, Inc. The local not-for-profit helps create job opportunities for people who have significant disabilities and other employment barriers. The Rise employees work on a variety of tasks including the plant’s recycling efforts, which have increased significantly in recent y

Indiana’s largest beer and wine distributor has announced it will convert 85 percent of its heavy duty truck fleet to Cummins Westport engines fueled by compressed natural gas. The Monarch Beverage Company is partnering with Cummins and several other companies on the project, which will include an on-site compressed natural gas fueling station to be completed by March, 2013. “As a family-own

Ten years in the making, Cummins Emission Solutions is demonstrating that a company can be green and profitable at the same time. Sales for the exhaust after-treatment maker have gone from nothing in 2002 to $1.2 billion in 2011 while Cummins Emission Solutions’ workforce has grown from just 11 employees to more than 1,400 today. “This is all about green jobs,” says Srikanth Padmanabhan, Vic

Construction started earlier this summer on a first of its kind project for Cummins that will use landfill gas and the Company’s combined heat and power (CHP) systems to provide industrial customers in Delaware with a clean, sustainable source of energy. The first recipient will be Croda Inc.’s Atlas Point chemical manufacturing plant in New Castle, Del. Croda, a global company with operations

For much of the past year, workers on the second shift at Tata Cummins Limited Plant 2 in Phaltan have witnessed something rarely seen on a shop floor in India after 7 p.m. Women. Women are now working from 2 to 10 p.m. in the plant at Cummins’ Megasite, about two hours southeast of Pune. They normally are not allowed to work past 7 p.m. but Tata Cummins is one of a select number of manufact

Besides being the preferred dinner for pandas, bamboo is the ecologically preferable source for high-end flooring, soft towels and ...buildings stronger than steel. Employees at Cummins Research and Technology India (CRTI) in Pune put their engineering skills to work so people in rural areas could have a lower cost alternative for building materials. The result was an Environmental Challenge